Diebold刀柄符合DIN 69893-1 HSK-E32

Diebold专门设计了刀柄,用于加工钛和氧化锆材料。 Diebold HSC刀柄具有涂层,因此可防止粘附污垢或锈蚀。这使Diebold成为HSC加工的理想选择,因为它要求高跳动精度和低不平衡程度。

Diebold CentroGrip?筒夹夹头的锥度和内径之间的跳动精度<1微米。

现在,客户正在寻求具有小于1微米的径向跳动的热缩夹具。要实现这些精度并不容易,但Diebold的巧妙设施和制造技术诀窍Diebold能够提供精度等级的刀架。

平衡质量:高性能刀柄的平衡质量变得越来越重要。如果所需的刀架在这些刀架设计的整个速度范围内平衡到G0,1。

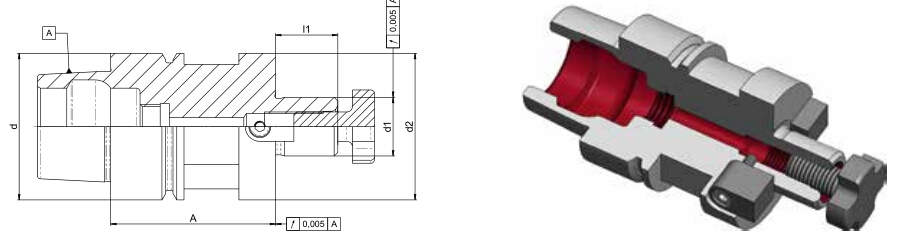

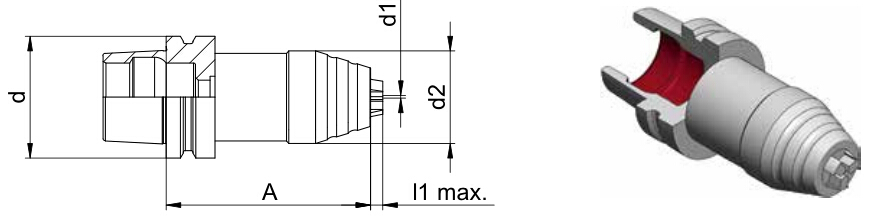

Diebold带有固定传动键铣刀柄

精确平衡G2.5 20,000转

应用:卷取刀头,锯片等。

供货范围:切刀拧紧螺钉和传动销。

| Order-No. | HSK-E | d1 | d2 | l1max | A | rpm |

| 72.563.120.200 | 3225 | 16,0 | 40,0 | 17,0 | 45,0 | 32000 |

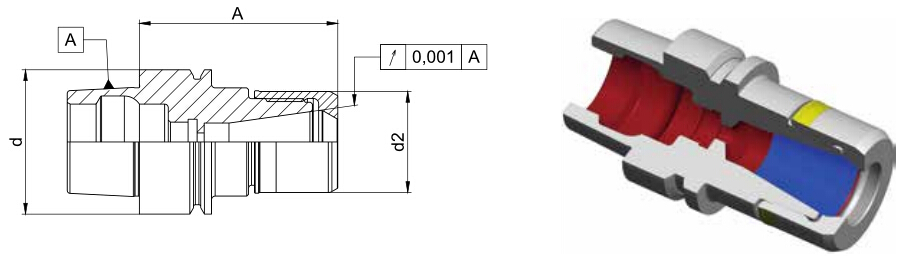

Diebold CentroGrip?高精度夹头刀柄

应用:高精度夹紧带圆柱柄的刀具。

交付:使用夹紧螺母和操作手册。

备注:使用特殊CentroGrip?扳手拧紧。

| Order-No. | HSK-E | d1 | d2 | l1max | A | rpm |

| 72.563.485.100 | 32 | 16 | 60 | MR11 | Mini | 40000 |

| 72.563.485.200 | 24 | 55 | MR16 | Mini | 40000 |

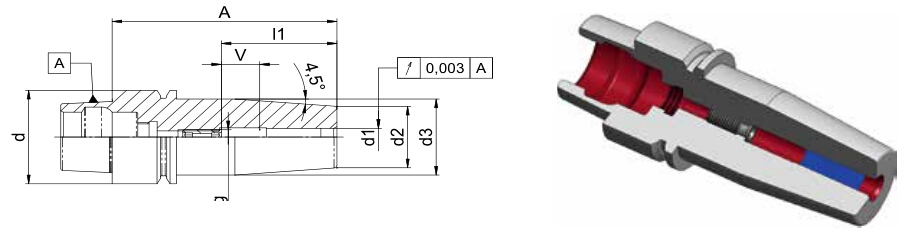

Diebold HSK Shrink Fit刀柄

应用:快速和安全地夹紧带圆柱柄的刀具。 我们的卸压孔易于操作(从?6mm开始)。 非常适合HPC和HSM等高RPM应用。

交货:带长度调节螺丝的收缩夹头。

备注:您可以将可用的感应收缩装置与Diebold Shrink Fit卡盘一起使用。 为了获得佳的工艺可靠性和夹头的长寿命,推荐使用ThermoGrip?收缩单元。

| Order-No. | HSK-E | d1 | d2 | d3 | l2 | A | g | HSS | V | rpm |

| 72.563.500.010 | 32 | 3,0 | 15,0 | 20,0 | 20,0 | 60,0 | M6 | - | 5 | 46000 |

| 72.563.500.040 | 4,0 | 15,0 | 20,0 | 20,0 | 60,0 | M6 | - | 5 | 46000 | |

| 72.563.500.070 | 5,0 | 15,0 | 20,0 | 25,0 | 60,0 | M6 | - | 5 | 46000 | |

| 72.563.500.100 | 6,0 | 21,0 | 26,0 | 36,0 | 70,0 | M5 | √ | 10 | 46000 | |

| 72.563.500.200 | 8,0 | 21,0 | 26,0 | 36,0 | 70,0 | M6 | √ | 10 | 46000 | |

| 72.563.500.300 | 10,0 | 24,0 | 29,0 | 42,0 | 70,0 | M8x1 | √ | 10 | 46000 | |

| 72.563.500.400 | 12,0 | 24,0 | 29,0 | 47,0 | 70,0 | M10x1 | √ | 10 | 46000 |

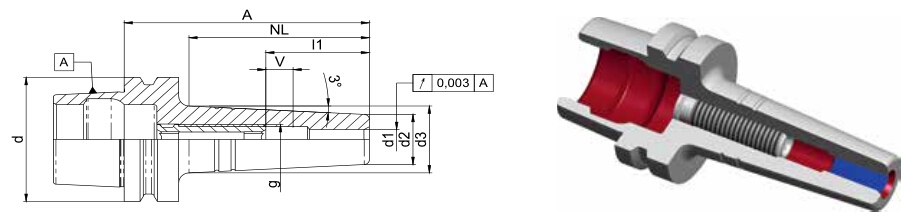

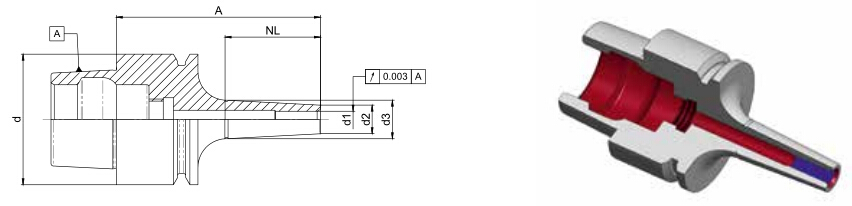

Diebold HSK ShrinkFit刀柄TSF Slim版本

精细平衡G2.5 25000 U /分钟

应用:快速和安全地夹紧带圆柱柄的刀具。 通过纤细的设计达到小的碰撞几何。 深腔的理想选择。

交货:带长度调节螺丝的收缩夹头。

注释:您可以将可用的感应收缩装置与Diebold Shrink Fit卡盘一起使用。 为了获得佳的工艺可靠性和夹头的长寿命,我们推荐使用ThermoGrip?收缩单元。

| Order-No. | HSK-E | d1 | d2 | d3 | l1 | A | NL | g | HSS | V | rpm |

| 72.563.501.010 | 32 | 3,0 | 9,0 | 13,0 | 20,0 | 64,0 | 40,0 | M6 | - | 5 | 50000 |

| 72.563.501.012 | 3,0 | 9,0 | 16,0 | 20,0 | 94,0 | 70,0 | M6 | - | 5 | 50000 | |

| 72.563.501.040 | 4,0 | 10,0 | 14,0 | 20,0 | 64,0 | 40,0 | M6 | - | 5 | 50000 | |

| 72.563.501.042 | 4,0 | 10,0 | 17,0 | 20,0 | 94,0 | 70,0 | M6 | - | 5 | 50000 | |

| 72.563.501.100 | 6,0 | 12,0 | 17,0 | 36,0 | 74,0 | 50,0 | M5 | - | 5 | 50000 | |

| 72.563.501.150 | 6,0 | 12,0 | 20,0 | 36,0 | 104,0 | 80,0 | M5 | - | 5 | 50000 | |

| 72.563.501.200 | 8,0 | 14,0 | 19,0 | 36,0 | 74,0 | 50,0 | M6 | - | 5 | 48000 | |

| 72.563.501.250 | 8,0 | 14,0 | 22,0 | 36,0 | 104,0 | 80,0 | M6 | - | 5 | 48000 | |

| 72.563.501.300 | 10,0 | 16,0 | 21,0 | 42,0 | 78,0 | 55,0 | M8x1 | - | 5 | 48000 | |

| 72.563.501.350 | 10,0 | 16,0 | 22,0 | 42,0 | 104,0 | 80,0 | M8x1 | - | 5 | 48000 |

Diebold HSK ShrinkFit刀柄TUS超薄版本

建议收缩装置:MS 502-P

精细平衡G2.5 25

| Order-No. | HSK-E | d1 | d2 | d3 | l1 | A | NL | g | HSS | rpm |

| 72.563.503.010 | 32 | 3,0 | 6,0 | 9,0 | 20,0 | 50,0 | 22,0 | - | - | 50000 |

| 72.563.503.040 | 4,0 | 7,0 | 10,0 | 20,0 | 50,0 | 23,0 | - | - | 50000 | |

| 72.563.503.100 | 6,0 | 9,0 | 12,0 | 36,0 | 50,0 | 24,0 | - | - | 50000 |

Diebold 微型钻头刀柄

精细平衡G2.5 25000 U /分钟

同心度<0.03μm

| Order-No. | Taper | d1 | d2 | l1max | A | rpm |

| 72.563.533.015 | 32 | 0,2-1,5 | 19,0 | 2,5 | 50,0 | 38000 |

| 72.563.533.030 | 1,5-3,0 | 19,0 | 2,5 | 50,0 | 38000 |

上海浦东康意路551号2号楼2楼西

上海浦东康意路551号2号楼2楼西

021-50396508

021-50396508